The COVID-19 pandemic has overwhelmed the U.S. meatpacking industry, but public health experts say the risks posed to workers and the U.S. food supply chain by airborne viral infections were readily apparent and could have been addressed years ago.

Ongoing virus outbreaks could have been avoided, and future illnesses eliminated, if major meatpacking plants had implemented disease-control measures recommended by the U.S. Centers For Disease Control and Prevention long before COVID-19 was first identified. The plants only began implementing such measures after workers started to get sick and die from the disease.

Now, as workers at shuttered plants are likely to return to work soon under a presidential order, federal regulators continue to suggest rather than require companies to implement basic safety measures, such as separating workers by six feet or more, promoting hand washing, issuing face masks and telling sick workers to go home.

One of the biggest COVID-19 outbreaks in the U.S. occurred at the Smithfield Foods pork processing plant in Sioux Falls. The plant was the nation’s largest COVID-19 hotspot for nearly a week in April. So far, nearly one-fourth of its workforce — more than 850 people — has tested positive for the virus that causes the deadly disease.

On April 29, state officials in Minnesota announced that about 500 workers at the JBS meatpacking plant in Worthington were positive for COVID-19; that plant shut down on April 20. Nationwide, several thousand meatpacking workers have been sickened and dozens hospitalized due to COVID-19. Some workers have died from the disease, including at least two in South Dakota.

Federal regulators, though, have been reluctant to force meatpackers to address the threat of airborne infections through regulation, even in light of COVID-19, and plant operators have not willingly implemented safety and reporting measures, some of which had been recommended for more than a decade.

On April 28, the federal Occupational Health and Safety Administration issued a “statement of enforcement policy,” saying it was vitally important that meatpackers implement guidance on how to handle COVID-19, issued jointly by OSHA and the Centers for Disease Control and Prevention.

The statement said OSHA would use “enforcement discretion” for employers adhering to OSHA/CDC guidance on COVID-19 and would take into account good faith attempts to follow the guidelines in the event of an investigation. The policy statement also said not implementing OSHA/CDC guidance could be used against an employer in the event of a lawsuit.

By relying on suggestions rather than regulations, OSHA has failed in its core mission to protect workers, said Debbie Berkowitz, an expert on the meatpacking industry who now serves as worker health and safety director for the National Employment Law Project in Washington, D.C.

OSHA has increasingly taken a hands-off approach to the meatpacking industry and has not enforced the COVID-19 guidelines set first in March and then again in April by the CDC, said Berkowitz, who has also worked as the health and safety director for the national AFL-CIO. The failure by OSHA to require rather than suggest safety measures for workers in the American meatpacking industry has created a situation where an illness such as COVID-19 can easily spread within the plants and to the public beyond, she said.

“OSHA has completely abdicated its responsibility to protect meatpackers,” said Berkowitz, who spent six years as chief of staff and a senior policy adviser for OSHA in the early 2010s and who once toured the Smithfield plant in Sioux Falls. “OSHA has set no specific regulations for meatpacking in regard to COVID-19 and they’re not enforcing the CDC guidance of six feet apart and masks for everybody.”

Experts say meatpackers and other industries missed an opportunity to learn from the H1N1, or swine flu, pandemic that struck in 2009, failing to implement safety suggestions made at that time to prevent the spread of future airborne illnesses in workplaces.

As recent as 2016, the federal Occupational Health and Safety Administration was drafting a rule that would have required employers to take steps to reduce the potential for airborne infections to spread, said Dr. Melissa Perry, an occupational health researcher with George Washington University. That effort was killed in 2017 and hasn’t been revisited since.

“There’s been a neglect in paying attention to the risks of airborne pathogens for workers since that time,” Perry said. “Prior to that, I know there had been multiple efforts to push forward an airborne pathogens standard.”

Officials in the meatpacking industry say that prior to COVID-19 outbreaks in packing plants, they had no idea that an airborne virus could pose a serious threat to workers and, by extension, the country’s food supply.

“I don’t believe there was any concern,” said Christopher Young, executive director of the American Association of Meat Processors. “I don’t believe there was any industry that was concerned. Everyone had normal workplace policies in place for employee welfare, but no one had ever experienced something like this.”

The latest recommendations from OSHA and the CDC also have been changing rapidly, Young said, which has made them more difficult for the industry to implement.

“Right now, the concentration is on following CDC guidelines for mitigating the risk to employees,” Young said. “That guidance seems to be changing quite often, so we are trying to make sure we stay up with it.”

In an April 24 statement aimed at addressing what it called “misinformation” about its response to COVID-19, Smithfield Foods officials said the company has done everything in its power to follow the CDC’s pandemic guidance and has kept most of its facilities operating in an effort to maintain the U.S. food supply, not to simply rake in additional profits.

“We are doing everything we can, as fast as we can. There are, however, inescapable realities about our industry. Meat processing facilities, which are characterized by labor intensive assembly line style production, are not designed for social distancing. Employees often work in close proximity on production lines. Similarly, space constraints exist in common areas such as cafeterias, break and locker rooms and bathrooms. These areas pose additional challenges.”

“Consequently, mitigating risk of COVID-19 transmission depends on implementing other aggressive actions, which have already been adopted companywide. We continue to actively monitor CDC guidance, as well as that of state and local health authorities, and are immediately taking all necessary actions to protect our employees,” the Smithfield statement said.

In addition to Smithfield, South Dakota is home to 28 other meat processing plants that are inspected by the U.S. Department of Agriculture and therefore allowed to sell products across state lines. As of April 29, nine cases of COVID-19 had been reported at the DemKota beef processing plant in Aberdeen, but no other positive cases were reported at other plants. The DemKota plant remains open.

Public health experts say at least some of the COVID-19 cases and meatpacking shutdowns could have been prevented if regulators and industry officials had taken the threat of disease among food workers more seriously.

“They have to redo their whole plants so they can keep workers six feet apart on the lines and throughout the plants. You’re going to see a second wave of this virus in Sioux Falls if they [meatpackers] don’t change the way they do business.” -- Debbie Berkowitz, worker health and safety director for the National Employment Law Project and a former OSHA official

Perry, who spent several years researching cutting injuries at pork processing plants in Iowa and Nebraska, said public health researchers have been concerned about the spread of disease in meatpacking plants for years. The conditions that tend to create a higher risk for cut injuries — workers standing close together, a grueling pace and incentives to never miss a day of work — also put workers at an increased risk of contracting and spreading airborne diseases such as COVID-19.

“It’s not surprising at all,” Perry said of the COVID-19 outbreaks in packing plants. “I think a lot of essential workers are facing risks, and when it comes to meatpacking, they would be at inordinate risk just simply based on how crowded the conditions are.”

However, there may be ways to quickly, safely and efficiently re-open shuttered meatpacking plants, Perry said. Line speeds can be slowed, meatpacking workers can be given priority for universal testing and access to government stockpiles of protective equipment, she said.

Such actions, though, will need federal requirements and enforcement, Berkowitz said.

“The 3,000 workers sick and 17 dead in the meatpacking industry is proof positive that voluntary compliance does not work in this industry and that there needs to be mandates,” Berkowitz said. “The reason it’s spread in that plant in Sioux Falls and in so many other meatpacking plants is that the companies prioritize profits over public health.”

A dangerous industry before COVID-19

Government data show that meatpacking plants are among the most dangerous workplaces in the country. In South Dakota over the past five years, major meat processors in the state have reported 16 hospitalizations due to workplace injuries and six amputations, most of which were fingers, according to a national severe injury database maintained by OSHA.

The fact the plants have become hot spots for COVID-19 was not surprising, said Rod Rehm, a Lincoln, Neb., attorney who has specialized in representing injured workers in lawsuits against meatpacking plants.

“They work in a dense workplace, and they wear different kinds of protective clothing, but I don’t think any of it is designed to protect them from breathing on each other or protecting against the coronavirus,” he said.

Rehm said that meatpacking companies he has sued often tried to minimize worker injuries or pressure workers to not report injuries or file complaints about unsafe working conditions.

“There are a lot of efforts taken to discourage reporting, and to make workers feel that they’re going to be treated poorly if they do report injuries and illnesses or seek treatment,” he said. “They’re going to be petrified to report anything. They always face ostracization, being treated differently by supervisors, even up to deportation.”

For workers who do become ill or injured, meatpackers often do what they can to keep workers on the lines, Rehm said.

“They have these little health clinics set up in packaging plants designed to treat symptoms and send them back to work,” Rehm said. “If workers do decide to report injuries, the companies all go to great lengths to send employees to doctors who favor the employers.”

A spokesperson for the Unified Food and Commercial Workers union Local 304a, which represents workers at the Smithfield plant in Sioux Falls, said the plant has a robust system for reporting injuries and that workers can actually be fired for not reporting an on-the-job injury. The spokesperson, who declined to be named citing a national union directive, said there have been no recent complaints lodged against the plant’s health clinic.

Until the 1970s, the meatpacking industry was home to a highly skilled workforce in which many employees were essentially butchers who broke down an entire animal, Rehm said. The introduction of the cutting line created a system of repetitive actions in which workers focused much more on speed and production, often making workplaces less safe. The plants also began to attract a workforce of immigrants who often feel powerless to demand safety improvements or report injuries or illnesses, Rehm said.

“It leads to the conditions where you have people on the margins who do hard physical work and don’t get paid a lot,” he said. “It’s a significant portion of the packing plants that are made up of immigrant labor, and the companies damn well know it.”

Threat of airborne disease ignored

As early as 2009, federal public health officials began to consider the idea that an airborne virus could wreak havoc inside essential workplaces such as hospitals, police departments and food-processors. That spring, a new strain of influenza known as H1N1, or swine flu swept the planet, causing the first flu pandemic in more than 40 years, according to the CDC.

The swine flu actually affected people under the age of 65 more strongly because they had never been exposed to a similar virus. Schools considered precautionary closures and the CDC warned that as much as 40% of the American workforce could be sidelined due to the illness.

By November of 2009, a vaccine for the swine flu was in circulation and the pandemic was declared over in August 2010.

While large scale economic shutdowns were avoided during the swine flu pandemic, public health officials in the U.S. treated the incident as a warning for pandemics to come and began developing new ways to handle the spread of airborne viruses. Among those efforts was a push at OSHA to develop rules aimed at preventing the spread of airborne disease and potential shutdowns at critical industries, such as healthcare and food production. The airborne pathogen standard was close to being finalized in 2016, Perry said, but the rules were killed and never revisited.

The CDC did create some pandemic flu-focused guides for employers, the latest versions of which were published in 2017. The CDC guidance includes such advice as encouraging sick workers to stay home, creating a plan to keep workers at least three feet apart and creating a plan to allow workers to stay home longer if they get sick or need to take care of sick family members. While the focus of the CDC guidance is on a flu pandemic, the principles apply to any airborne virus.

Guidelines, though, don’t obligate employers to do anything, and when it comes to the meatpacking industry, they largely didn’t, until COVID-19 started killing workers.

“Most companies just had general workplace policies in place for the health and safety of their workers,” Young said. “People that work in the meat processing industry are given personal protective equipment to wear depending on the job they are performing but those usually do not include face masks.”

The U.S. Government Accountability Office signaled in a study in 2005 that meatpacking plants needed to improve worker safety, and the GAO reported again in 2016 and 2017 that meatpacking plants had worker illness rates that were four times higher than in other manufacturing sectors. Those reports also noted that meatpacking workers felt discouraged by plant officials from reporting injury or illness, and that medical protocols in plants were outdated or inefficient.

Over the past four years, meat packing companies have sought dozens of waivers seeking to speed up their processing lines. Some pork plants are processing as many as 1,100 animals per hour. During the current pandemic, chicken processing plants have sought 11 separate waivers seeking to allow plants to move 140 chickens per minute through their lines. The pace forces workers to work shoulder to shoulder to keep up.

Working so closely together makes the spread of disease more likely, said Dr. William Schaffner, a public health expert and professor of preventive medicine at Vanderbilt University.

“By and large, the working conditions are far from ideal for personal health,” Schaffner said. “There’s a lot of intense work and they work very closely together.”

A CDC investigation of the Sioux Falls Smithfield plant, after it was shut down in April due to its COVID-19 outbreak, also found that workers were forced to pack tightly together in order to punch in for their shifts, take breaks or use their lockers. When social-distancing recommendations were made to fight COVID-19, Smithfield workers say they simply couldn’t follow the advice and still do their jobs.

“The union did give us awareness about washing hands and to try to keep a social distance,” said Achut Deng, who has worked at the Smithfield pork processing plant in Sioux Falls for six years. “It was too hard to do that because, at my workplace, people are working shoulder to shoulder.”

Deng said some workers weren’t all that worried about the threat of disease spreading through their ranks prior to the COVID-19 pandemic. Even after the disease started shutting down businesses across the country, workers at Smithfield said they didn’t give it much thought.

“Did we take it seriously? I didn’t, and it was the same for most of my co-workers,” said Deng, who tested positive for COVID-19 on April 4.

The fact that workers weren’t all that concerned about COVID-19 points to another challenge for public health in the meatpacking industry — its diverse workforce, said Perry, the GWU researcher.

Meatpacking relies heavily on immigrant labor. Nationally, about a third of the industry’s workforce are immigrants, so multiple languages can be spoken in any given plant. In some of the packing plants Perry was researching in, as many as 10 different languages were spoken, she said. At the Smithfield plant in Sioux Falls, as many as 40 different languages are spoken.

Illnesses, such as the flu or COVID-19, also tend to spread among lower-income populations, such as the many immigrants who work at Smithfield and other meat plants, Schaffner said. Due to low pay, many meat plant workers often live in cramped quarters that allow for the spread of viruses at both home and in the workplace. Many also do not have adequate access to health care, he said.

To date, there are no rules that require employers to make sure their employees can actually understand the information they’re distributing about the threat of disease. In fact, the CDC investigators dispatched to Sioux Falls noted in their April 23 report that when Smithfield workers started being sent home sick with COVID-19 symptoms in March, they were given packets of information about what to do next but the information was only printed in English.

“When we’re talking about infection control and information, the plants have to be responsible for translating all of that information into languages that workers will understand,” Perry said.

The way meat processors have incentivised workers to stay on the job at all costs has likely contributed to the COVID-19 pandemic’s impact on the industry, Perry said. The Smithfield plant in Sioux Falls, for example, offered employees a $500 bonus if they didn’t miss a day of work during the pandemic before it shut down. However, employees were told if they were sent home due to COVID-19, they would still be eligible for the payment. Smithfield wasn’t alone in offering such bonuses.

From a disease control standpoint, attendance bonuses are a bad idea, Perry said. They encourage employees to come to work whether they feel ill or not. In the case of COVID-19, a disease for which as many as 80% of infected people will show only mild symptoms — if they show any symptoms at all — incentivising even mildly sick workers to keep punching in has the potential to spread a disease far and wide among workers.

“Any kind of policy that disincentivizes people taking time off for sickness is going to increase risk for infection in the plants,” Perry said. “Those practices have to be really redesigned to ensure that they’re not incentivizing sick people to come to work.”

Now, Americans are being told to brace for widespread shortages or much higher prices for pork, beef and even chicken — the country’s main sources of protein. On April 24, Tyson Foods, one of the four major meatpacking companies in the U.S., took out a full-page ad in the New York Times saying the nation’s food supply chain is breaking down. U.S. Sen. Mike Rounds, R-South Dakota, called the situation a “food crisis” in an April 26 letter to U.S. Vice President Mike Pence.

As much as 30% of America’s pork processing capacity, as well as up to 25% of the nation’s beef processing capacity, has been shut down due to plant closures as the disease has run rampant among workers. The meat processing slowdown has caused a backlog of animals waiting to be sent to a processor and has farmers wrestling with the prospect of euthanizing millions of animals that can’t be sold.

In his letter, Rounds said the number of cattle, pigs and chickens at farms and ranches across the country was at a breaking point and called for immediate federal action to protect food workers before packing plants can reopen, and to help farmers euthanize and dispose of unsellable livestock.

“The inability to develop a commonsense national plan to protect food workers and public health, while simultaneously operating the nation’s critical food infrastructure, is failing farmers, ranchers, food workers and consumers,” Rounds said.

Citing threats to the American food supply due to plant closures, President Donald Trump signed an executive order on April 28 that used the Defense Production Act to classify meat processing as a critical industry and order packing plants to remain open during the pandemic.

Changes needed to enhance safety

Public health experts say there are several things federal regulators and the meat packing industry need to do before reopening closed processing plants. One of the first things is creating a broad, federally coordinated testing program so sick workers can be identified quickly and sent home to recover before spreading the disease, Perry said.

“These are essential workers, and in order for essential workers to perform their jobs safely, they have to be working in an environment that is virus free,” Perry said. “In order to know whether or not the environment is virus free, people have to be tested.”

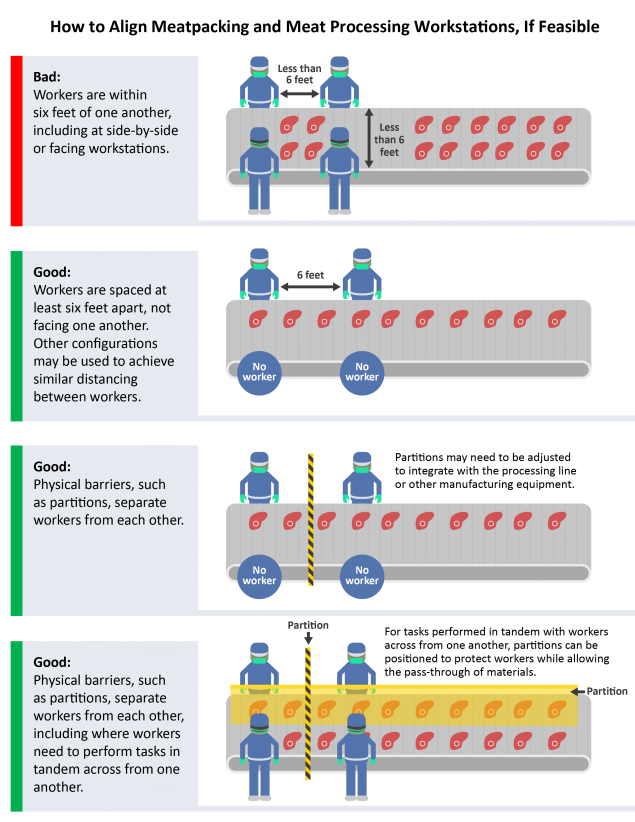

Meatpackers also will need to slow down their production lines, spread workers out on their lines and find new ways to keep workers at least six feet apart when they’re at lunch or taking a break.

“Given the pace at which work proceeds in meatpacking, you have to ensure that workers are given adequate breaks, adequate protections, adequate guidance as to how they can perform their work safely and, in this context with infections, adequate access to water sanitation and hygiene,” Perry said.

Schaffner said OSHA, as the principal workplace safety regulator, must engage in a process of adopting CDC guidelines as regulations, but that he expects improvements will come slowly.

“Try to get them to move on any issue; it’s not easy,” he said. “In public health, it’s not a steady stream of improvement. It’s two steps forward, one step back; two steps forward, one step back, and you have to keep on keeping on.”

Congress has signaled at least some interest in changing workplace safety regulations to include COVID-19. In early March, Democrats in the U.S. House of Representatives submitted a bill that would require OSHA to develop an emergency “infectious disease exposure control plan to protect employees” in health care and other at-risk industries. Action on that bill likely will take months.

In the meantime, without firm regulations in place regarding COVID-19 and other airborne diseases, meatpacking companies large and small are making worker safety decisions on their own.

Bruce Anderson, owner of Western Buffalo Company in Rapid City, said he took it upon himself to provide face masks to his employees and to urge them to ride separately to work, though he acknowledges some employees have ignored his suggestions. He has also monitored employee illnesses and required workers to stay home if sick.

“We’re paying attention to this, and we’re not going to let something bad happen,” Anderson said.

Before closing down, the Smithfield plant in Sioux Falls, too, made an effort to improve worker safety. As noted in the CDC investigators’ report, plant managers installed barriers between workstations and at lunch tables, began checking worker temperatures before they started their shifts and put more effort into sanitizing non-work spaces.

Anderson said he expects the meatpacking industry will make major improvements to prevent future worker illnesses.

“The packing industry will address this and do a good job; they will spread these people out,” Anderson said. “They’re going to take a harder look at robotics after this, I can guarantee you that. I know the industry will react favorably to this.”

In the longer term, federal regulators will need to get more aggressive, Berkowitz said.

Meatpackers such as Smithfield, JBS, Tyson and Cargill will have to spend money to expand and alter plants to protect workers from COVID-19 or any other airborne illnesses that come along. For the time being, tents may have to be erected next to plants to provide workers with a safe environment during the unregulated periods in which they are on break or in lockers rooms, she said.

“They [CDC] essentially said they have to redo their whole plants so they can keep workers six feet apart on the lines and throughout the plants,” Berkowitz said. “You’re going to see a second wave of this virus in Sioux Falls if they [meatpackers] don’t change the way they do business.”